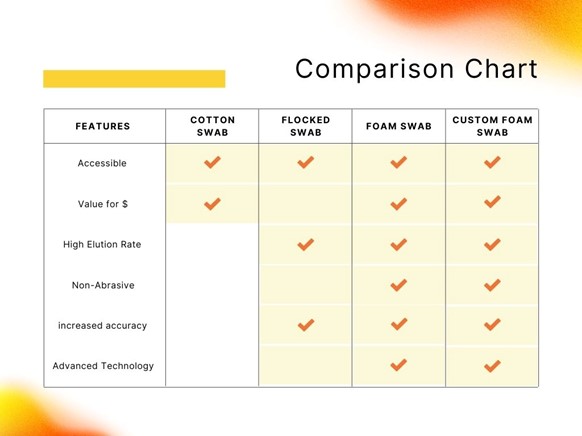

When it comes to diagnostic testing, choosing the right swabs can make all the difference in the accuracy of the results. When choosing a swab, what critical characteristics are you seeking? Different tip materials have different chemical and physical characteristics affecting swab performance. Consider the most common swab materials and what they do best.

Foam Swabs – Polyurethane-based, open-cell formula allows the specimen to stay on the surface for easy elution or release. (Zasada et al, 2020). Foam swabs provide a soft, non-abrasive surface compared to other options. Foam swabs are non-toxic and non-irritating, which makes them safe for sensitive areas. Foam swabs are commonly used for various diagnostic applications, including viral and bacterial cultures and antigen testing.

Strengths:

-

- Highly absorptive

- Non-abrasive

- Large surface area

- Reduced opportunity for specimen contamination

Weaknesses:

-

- May interfere with some assays

Flocked Swabs – Nylon-based, high absorption of buffer and liquids. Solid construction allows specimens to stay on the surface for easy elution or release. Can be more expensive than foam or cotton swabs and unsuitable for all diagnostic testing. Flocked swabs are commonly used for various diagnostic applications, including viral and bacterial cultures, molecular diagnostic tests, and antigen testing.

Strengths:

-

- High specimen collection

- High sample collection and release

Weaknesses:

-

- Can leave residue on rough surfaces

- Expensive to manufacture

- Abrasive

Cotton Swabs – Organic material, readily available for general use but typically not specific to a diagnostic test. Substances and fibers can interfere with some assays. A smaller surface area than other options may make it more challenging to collect an adequate sample. Absorption may not be suited to the specimen type. They are commonly used for wound cultures, urethral swabs, and ear swabs, among other applications.

Strengths:

-

- Low cost

- Easy to use

Weaknesses:

-

- May contain substances that can interfere with some assays

- Inefficient specimen release

- Not suitable for all diagnostic tests

Choosing the Right Swab

The expanding testing industry demands greater selectivity depending on the type of specimen being collected and the area of the collection site. No longer can the most appropriate testing vehicle be determined by what has always been used. Advanced technology has improved diagnostic testing. Newer swab types offer improved accuracy and must be considered a critical advancement in testing processes and, subsequently, the accuracy of the results.

It is essential to select the right size and shape of the swab based on the anatomical site being sampled to ensure an adequate sample can be collected. If you want a custom diagnostic swab, Foamtec Medical can make custom swabs for your specific swab requirements.

Foamtec provides quality, consistent, and highly traceable materials through our vertically integrated manufacturing process. Our swabs are manufactured in our ISO 8 cleanroom facility and are made in the USA.

Foamtec swabs are designed with a high-performance mind to provide our customers with superior results.